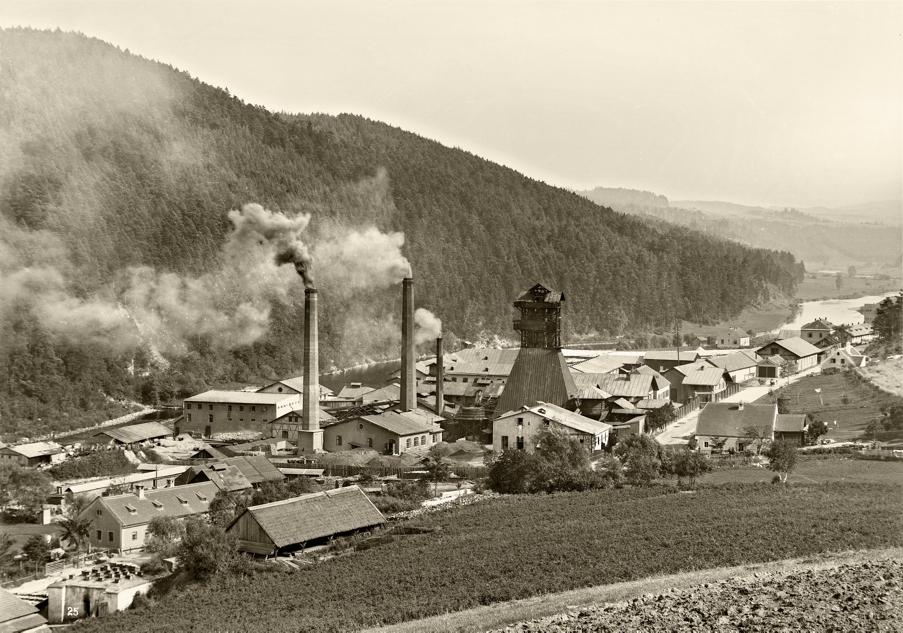

One of the largest Bohemia paper-mill is only 5 km away from the Český Krumlov Castle.

The first written notice about its history is in 1867. The tradition of paper manufacturing in Český Krumlov started four centuries before.

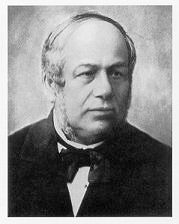

The history of the Větřní papermill had been preceded by Ignac Spiro , a paper-processing businessman,

who came to Český Krumlov and bought the local second papermill, established in 1792, from Theodor Pachner in 1861.

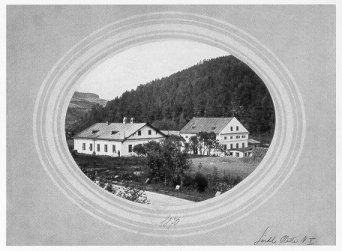

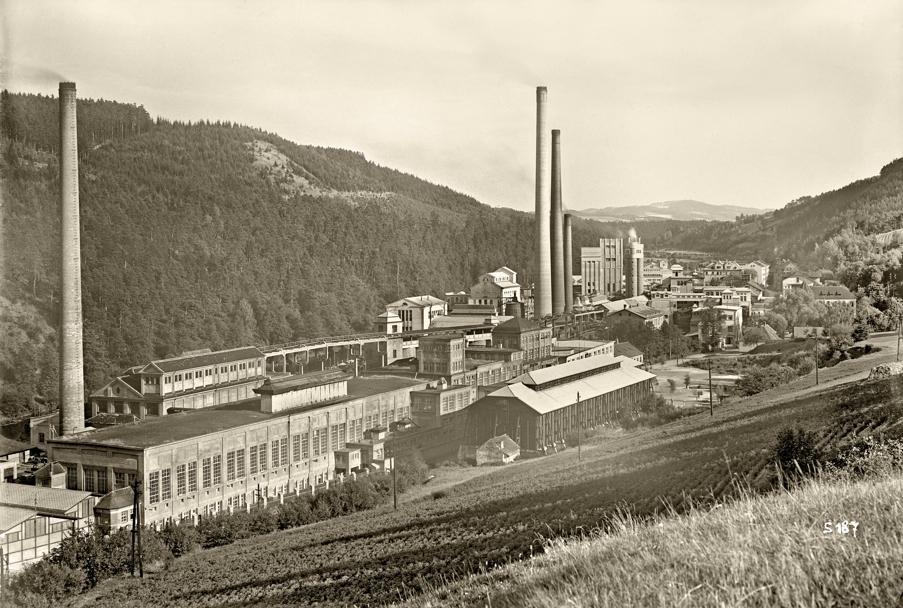

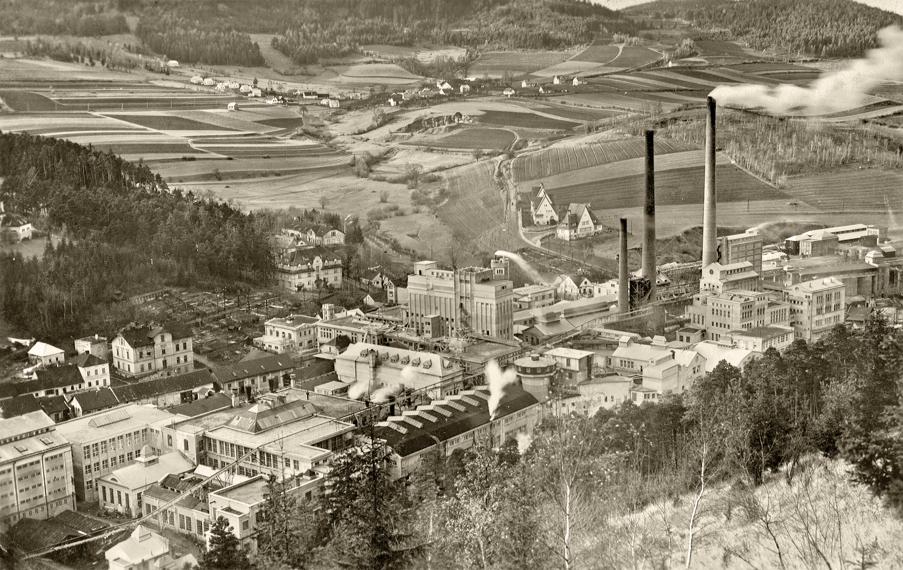

Due to the production extent Spiro was forced to buy The Pečkovský mill near Větřní in 1867. First intended as a pulp mill for the Český Krumlov papermill.

Nine years later there were already three paper-processing machines. The plant was the bearer of the progress in paper-processing technology all over Austria-Hugary,

and later in the independent state as well. In 1883 a sulphate wood pulp machine was launched. In 1911 the world largest paper-processing machine to manufacture rotary print paper was constructed.

In 1926 the Spiros family, as the first in republic, introduced the production of sulphate cellulose. A hydroelectric power station from 1903 in Vyšší Brod belongs to Spiro´s interesting achievements of technology.

Its power at the voltage of 15,000V was supplied to the paper-mill and adjacent parts of South Bohemia. Spiro´s factory in Větřní located the later established national enterprise Jihočeské papírny.

The beginning and early development of the first Český Krumlov paper-mill, Vít Kašpar was its possessor.

The second paper-mill was established in the town of Český Krumlov , namely the place where Ignac Spiro was in business in subsequent years.

Theodor Pachner sold the Český Krumlov papre-mill to Ignac Spiro.

Ignac Spiro bought the Pečkovský mill below Větřní and constructed a pulp mill.

The first machine to produce newsprint paper was constructed at the Pečkovský mill of Větřní. It was the largest and most modern machine all over the world at that time.

A new machine to produce rotary printing paper was constructed in Větřní. It was the largest machine in Central Europe at that time.

The national enterprise of South Bohemia Paper-mill Větřní was established.

The establishment of production-economy unit – the national enterprise of South Bohemia Paper-mill Větřní near Český Krumlov included paper -mill enterprises of Větřní, České Budějovice, Loučovice, Tábor, Přibyslavice and a section of Červená Řečice.

The establishment of joint-stock company South Bohemia Paper-mill Větřní and its paper-mill enterprises of Větřní, České Budějovice, Přibyslavice and Červená Řečice.

The transformation of joint-stock company South Bohemia Paper-mill Větřní into the holding type company with its main and filial companies. JIP Paper-mill of Větřní, a.s., became part and parcel of it.

Launching a new natural gas container , reduction of gas exhalation and fly-ash.

A property-share sale in filial companies apart from Větřní.

Stopping the two most efficient paper-processing machines, paper bag production, manufacture of imprint papers and unbleached sulphite cellulose.

The reconstruction of paper-processing machine No. 8 manufacturing wrapping papers- the increase in output and quality.

The reconstruction of paper-processing machine No. 6 manufacturing fine wrapping papers – the increase in output.

The reconstruction of paper-processing machine No. 4 manufacturing newsprint papers – the increase in output.

The partial reconstruction of paper-processing machine No. 7 manufacturing SC paper – the increase in quality and output.

The company was earmarked and sold from the group Jihočeské papírny, a.s. to a new owner.

JIP – Papírny Větřní, a.s. operates papermill Lukavice in Moravia as a tenant (January 2010 until June 2013).

PM 7 end of magazine SC papers production and beginning of a reorganization of the producing program focused on wrapping papers (shutdown in June 2013).

The beginning of Hurum section for processing used beverage cartons (shutdown due to unprofitability in 2019).

PM 4 the renewed production of wrapping paper after an overhaul of the machine.

PM 8 was shutdown due to unprofitability.

Stabilization of the company with an aim to strenghten its position in the market of wrapping paper on PM 4 and PM 6.

PM 4 and PM 6 new control systems. PM 6 a new grinding line.

Screw press S-PRESS 2 Industry for dewatering papersludges from the Huber company.

Screw press HUBER CS spol. s.r.o. (the magazine vodní hospodářství 5/2023)

Screw press HUBER CS spol. s.r.o. (the magazine vodní hospodářství 5/2023)